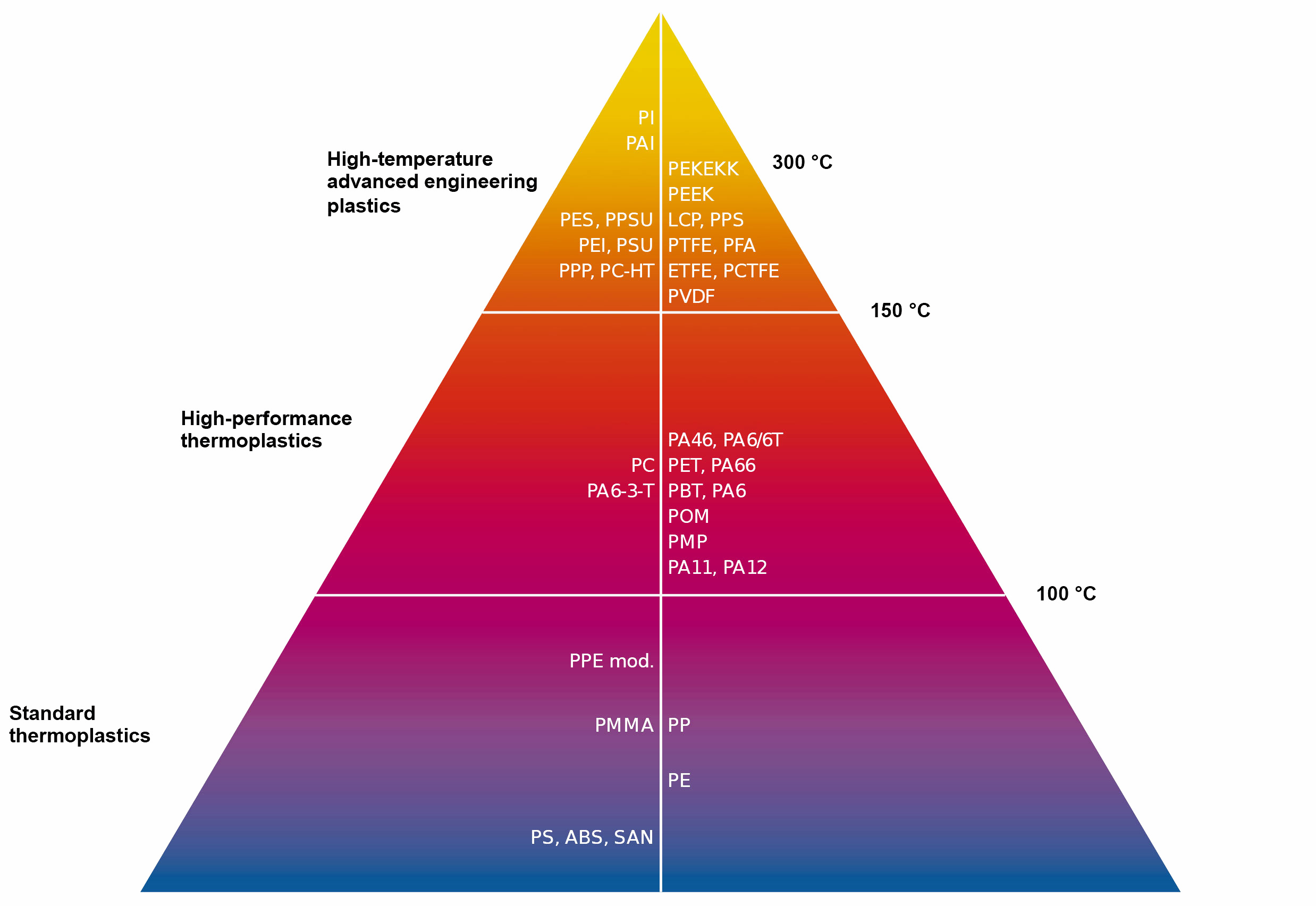

CLASSIFICATION OF PLASTICS

| POLYMER | ACRONYM | MAIN FEATURES |

|---|---|---|

| POLYIMIDE | PI | Depending on the type, they provide high strength with a low level of creep and good abrasion resistance for a continuous use at a temperature up to 300 °C, dimensional stability, electrical insulation, high purity, low outgassing. Suitable for mechanically and thermally stressed components. Inherently flame retardant. |

| POLYAMIDE-IMIDE | PAI | High mechanical resistance, low level of creep, high chemical resistance. Good abrasion resistance, low thermal expansion. Inherently flame retardant. |

| POLYETHERETHERKETONE | PEEK | This polymer has excellent properties, including a low level of creep and high elasticity modulus. Excellent tribological properties, especially abrasion resistance. Excellent resistance to various aggressive chemicals. FDA approved and physiologically inert. Inherently flame retardant. |

| POLYETHERKETONE | PEK | Improved properties compared to PEEK. Very good abrasion resistance. Suitable for high load dynamic applications. Excellent chemical resistance. Inherently flame retardant. |

| POLYETHERSULFONE | PES | Good electrical and dielectric properties. Suitable for food contact. Inherently flame retardant. |

| POLYPHENYLSULFONE | PPSU | Good impact strength, chemical resistance and hydrolysis resistance. Inherently flame retardant. Suitable for food contact. |

| POLYETHERIMIDE | PEI | Excellent mechanical and electrical properties. Inherently flame retardant. Suitable for food contact. |

| POLYSULFONE | PSU | High resistance, rigidity and hardness, low moisture absorption and excellent dimensional stability. Inherently flame retardant. Suitable for food contact. |

| POLYPHENYLENE SULFIDE | PPS | High chemical resistance, low level of creep, high dimensional stability due to low moisture absorption, high elasticity modulus. Inherently flame retardant. |

| POLYVINYLIDENE FLUORIDE | PVDF | High resistance, rigidity and hardness, low moisture absorption and excellent dimensional stability. Inherently flame retardant. Suitable for food contact. |

| POLYAMIDE FROM POLYTETRAMETHYLENEADIPAMIDE | PA46 | Good thermal insulation. Particularly suitable for sliding and wearing parts, which are exposed to high temperatures. High abrasion resistance. |

| POLYAMIDE FROM HEXAMETHYLENEDIAMINE | PA66 | Good rigidity, hardness, wear resistance, and dimensional stability. Good dynamic properties, FDA compliant types available. Suitable for parts exposed to higher mechanical and heat loads. |

| POLYETHYLENE TEREPHTHALATE | PET | Good tribological properties in moist or dry environments, high dimensional stability and low thermal expansion, low moisture absorption, good dielectric properties, good chemical resistance. FDA compliant. |

| POLYCARBONATE | PC | Amorphous, transparent material with excellent impact strength. Permanent operating temperature 120 °C, good mechanical strength, low level of creep and excellent dimensional stability. Suitable for food contact. |

| POLYBUTYLENE TEREPHTHALATE | PBT | High strength and low wear with high dimensional stability and good sliding properties. Extremely high rigidity with low thermal expansion coefficient due to glass fibre reinforcement. |

| POLYAMIDE FROM ε -CAPROLACTAM | PA6 | Semi-crystalline thermoplastic with good damping properties, good impact strength and high resilience even at low temperatures, good wear resistance, especially against rough frictional surfaces. |

| POLYOXYMETHYLENE (POLYACETAL RESIN, POLYFORMALDEHYDE) | POM | Semi-crystalline POM-copolymer with good mechanical properties, low moisture absorption, good fatigue strength and rigidity, good dimensional stability, and possibility to obtain narrow tolerances. Good sliding properties. Suitable for food contact. |

| POLYAMIDE FROM DODECANOIC ACID | PA12 | Excellent abrasion resistance and good chemical resistance. It is the polyamide with the lowest moisture absorption. Suitable for food contact. |

| POLYPHENYL ETHER | PPE | Excellent electrical insulation, easy to bond and weld, good mechanical properties and high resilience, resistant to hot water. |

| POLYMETHYL METHACRYLATE | PMMA | Transparent thermoplastic often used as an alternative to glass due to its light weight and shatter resistance. This is why is often called “acrylic glass”. |

| POLYPROPYLENE | PP | Excellent electrical insulation, extremely low moisture absorption, excellent chemical resistance, low density, easy to weld, can be FDA compliant. |

| POLYETHYLENE | PE | Excellent electrical insulation, extremely low moisture absorption, good tribological properties, good impact strength at low temperatures, easy to weld, resistant to various acids and cleaning agents, low density. Can be FDA compliant. |

| ACRYLONITRILE STYRENE ACRYLATE | ASA | This amorphous polymer belongs to the styrenics family. It can be considered halfway between ABS and PMMA (but it is not transparent). Intrinsic high resistance against UV rays (as PMMA) combined with good toughness in terms of impact strength (typical of ABS). |

| STYRENE ACRYLONITRILE | SAN | SAN is transparent, glossy, and scratch resistant. High chemical resistance, high rigidity and surface hardness. |

| ACRYLONITRILE-BUTADIENE-STYRENE COPOLYMER | ABS | Excellent electrical insulation, low moisture absorption, good damping properties, good bonding characteristics, high impact strength and rigidity. Resistant to diluted acids and cleaning agents. |

ADDITIVATION

The properties of the materials can be modified for specific applications using additives.

Via Tintoretto 1/A

31056 Roncade (TV) - Italy

tel. +39 0422 708159

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

P.iva: 04440290270 - C.F. 04440290270 - Rea: TV-407825

Reg. Imprese CCIAA TV/BL 04440290270 - Cap. Soc.: € 10.000,00 I.V. - Pec: This email address is being protected from spambots. You need JavaScript enabled to view it.